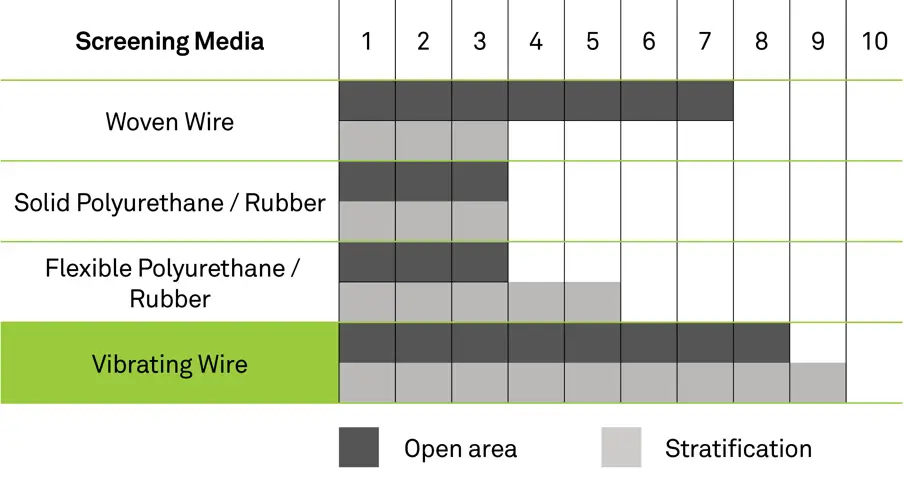

FASTER STRATIFICATION PROCESS

Vibration is the essential action needed when screening material. It allows coarse material to rise to the top and fine material to fall to the bottom.

When using static screening media (woven cloth, polyurethane or rubber panels, etc.), the only vibration is induced by the screen box which typically vibrates with a range of 500-1,000 strokes per minute. FLEX-MAT high-vibration wire screens have individual wires that vibrate independently at a high-frequency of between 6,000-10,000 strokes per minutes.

FLEX-MAT accelerates the stratification process and allows more material to pass through the screen.

OUTSTANDING

BENEFITS

MORE SCREENING EFFICIENCY

- Fastest material stratification

- More open area

MORE WEAR LIFE

- Made with OPTIMUMWIRE

- Flat surface & faster material passing

MORE PROFIT

- Pays for itself in days

- Better quality product in spec

- Less downtime and maintenance costs

INDUSTRY-LEADING WIRE TECHNOLOGY

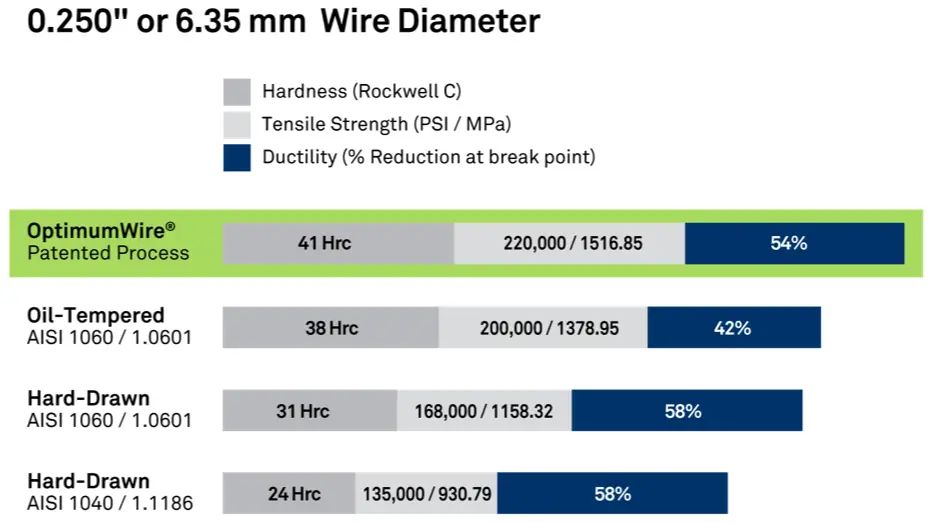

A wire’s quality plays an essential role in a screening media’s performance. The effective quality of wire depends on the right balance of these three factors.

MAJOR ensures optimum wire quality and consistency at all times by developing, through its own specifications and internal laboratory quality controls, the best recipe for a wire’s chemical content to optimize all factors. By using the most advanced patented wire-making process, MAJOR also only uses the highest quality of stainless steel wires with the highest tensile strength, available in Type 304 and Type 316.

Hardness

Resistance to abrasion and wear

TENSILE STRENGTH

Resistance to failure/breakage under stress

DUCTILITY

Capacity to support stress and to be formed without breaking or losing its properties

our unique processes

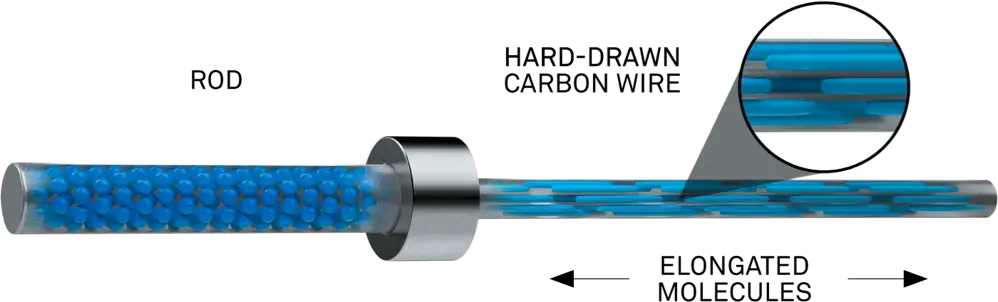

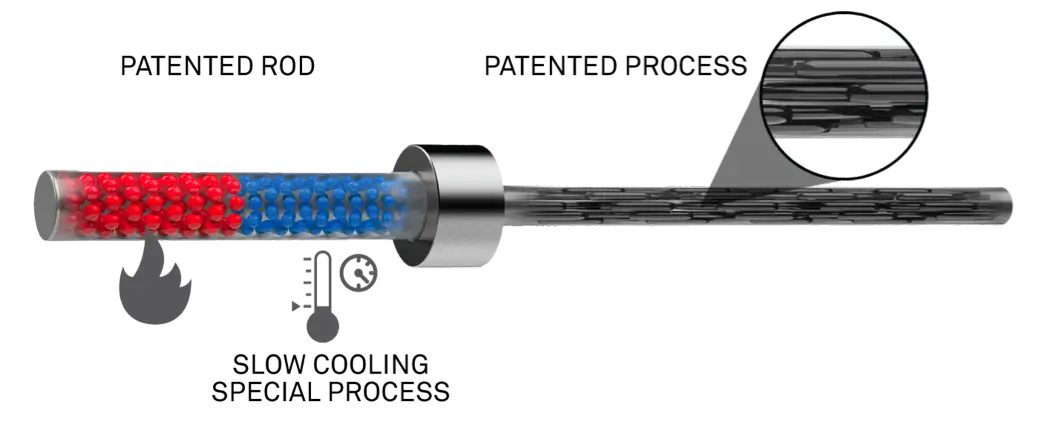

Hard or Direct-Drawn Process

This is the basic process to make a wire by having the rod drawn through a conic die to a specific dimension (in one or several sequences).

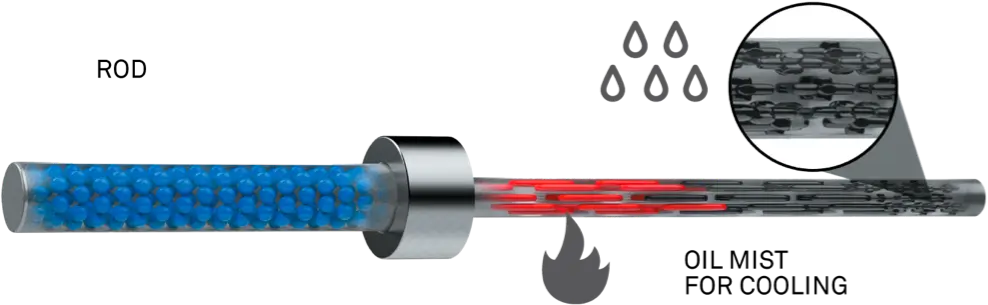

Oil-Tempered Process

This process is an attempt at improving the molecular structure. The rod is drawn through a conic die, then heated and then oil quenched.

Patented Process

This process is the ultimate way of improving the molecular structure. The rod is heated first and then cooled at a controlled temperature to optimize the molecular structure before being drawn through a conic die.

Independent analysis shows the superiority of MAJOR’s wires.

View which technologies are right for you

GREATER

OPEN AREA

Open area is the surface aperture (opening) of a screening media that allows material, pulled by gravity, to pass through. The greater the open area, the greater the screening capacity.

Open area varies with the screening media type and affects the tonnage or volume of material that can be processed on a screen deck. On screen boxes with multiple decks, the relation of open area and material gradation between the decks is an important efficiency factor that needs to be balanced.

By using the highest quality wires, MAJOR is able to decrease its wire diameters, which increases open area and throughput, while providing superior wear life.

LONGER WEAR LIFE

FLEX-MAT high-vibration wire screens offers longer wear life than woven wire screens and, depending the application, outlasts polyurethane and rubber media.

Its flat surface offers 100% of surface wear, compared to only the upper “knuckles” of woven screens, which results in the even wear of its wire, maintaining the opening within the given specification for a longer time. Polyurethane panels, however, lose opening specification after a certain percentage of wear due to the slight “V” shape of the opening.

Longer wear life reduces downtime as well as maintenance and replacement costs.

NO BLINDING, PEGGING OR CLOGGING

The action of vibrating wires eliminates blinding, pegging and clogging problems, even with humid material or rainy conditions.

Designed to provide high-performance on all decks for a wide range of materials, FLEX-MAT screens provides the highest-efficiency level of self-cleaning capacity for higher throughput, reduced downtime as well as maintenance and replacement costs.

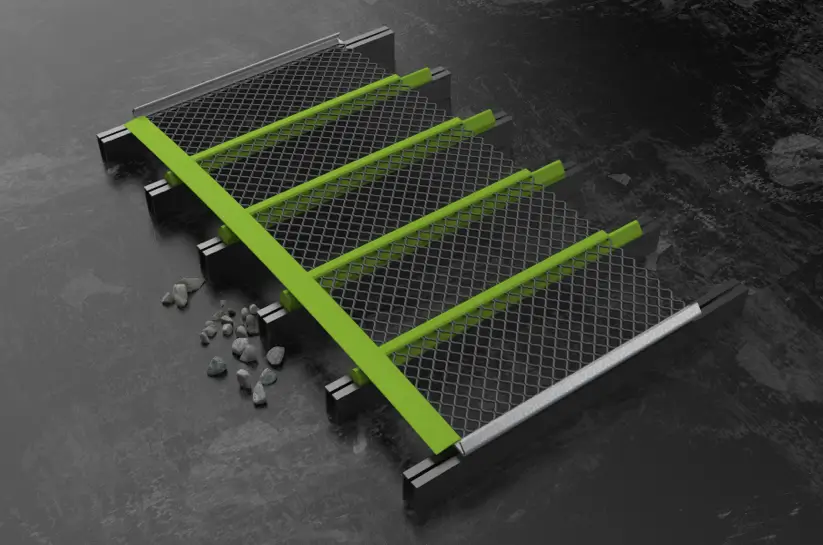

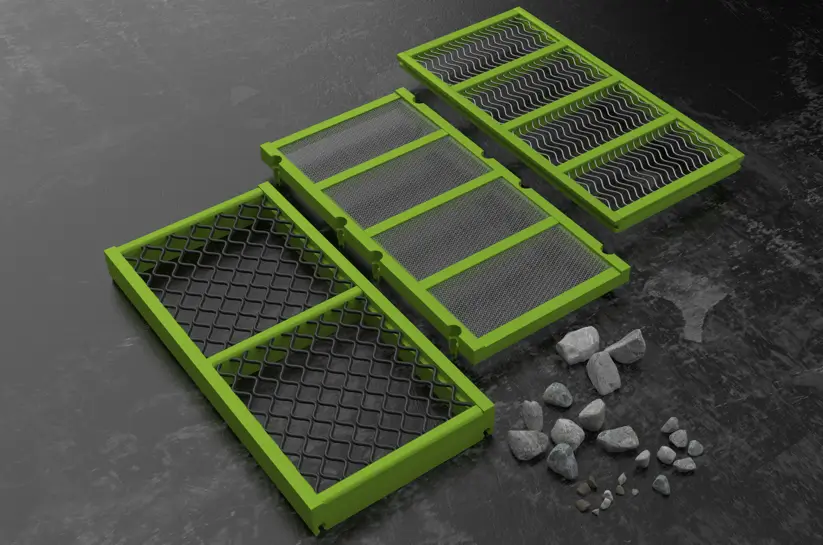

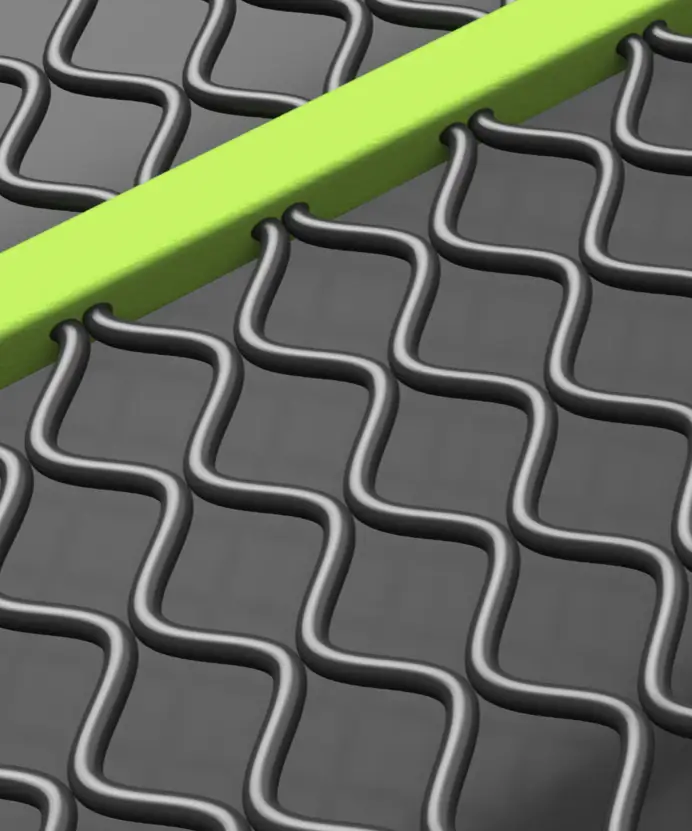

Vibrating wire screens and panels

This is the ultimate innovation in screening media. Wires are not woven and instead are individually held by cross polyurethane strips which can be highly tensioned, allowing them to vibrate at high frequencies under material action. This speeds up the stratification process while providing the maximum open area. It also provides the lowest cost per ton with a high-yield production capacity, while eliminating blinding and pegging issues.